Your Temperature Measurement Experts

Mini Case Studies from the Field

Temperature Measurement on a Mixing Vessel

Application

A peanut butter manufacturing facility produces their product in large mixing vessels. Temperature is a critical parameter in the production process that takes place in these vessels. Tank heaters are used to control the temperature of the mix and is crucial to creating a uniform peanut butter consistency.

Challenge

The vessels are using thermowells that are welded into the bottom side of the tank to insert temperature sensors into the mix. However, with this method the temperature measurement takes place at the bottom of the tank and is not representative of the product being mixed. There is also a significant time lag between when the tank heaters are turned on and when the heat effect reaches the sensors. Temperature sensors cannot be placed in mixing portion of the tank for they will interfere with the mixing blades.

Solution

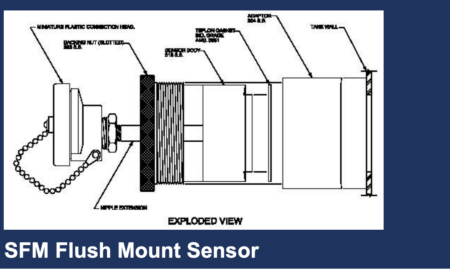

The solution for measuring temperature in a mixing vessel is to use the Burns flush bulb assembly. The flush bulb, as the name implies, is mounted so the sensing surface is flush with the interior wall of the vessel. There is no hardware intruding into the tank so the mixing blades and sweeper paddles will not be interfered with. The sensor can be mounted anywhere on the tank that is suitable for the best measurement. Since the control loop lag time can be shortened, there is less risk of overheating the product.