Your Temperature Measurement Experts

Mini Case Studies from the Field

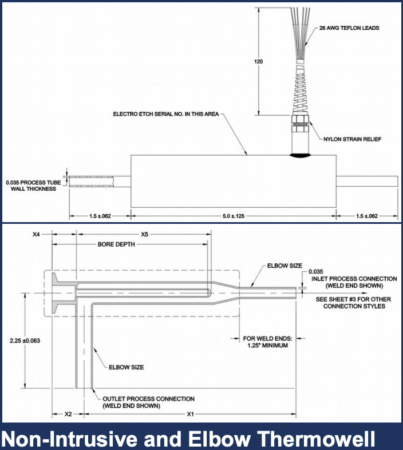

Temperature Measurement in Really Really Small Lines

Application

Measuring fluid temperature accurately in small diameter lines can be difficult. When the tube size drops below 1/2” and the operating temperature goes up to 800°F, it gets even more difficult. A manufacturer required a temperature measurement of a fluid flowing in a 1/4” tube with a maximum temperature of 800°F. Pressure and flow rates were low but the ambient conditions included the possibility of being warm, wet, and humid.

Challenge

Off-the-shelf solutions are not suited for installation in a 1/4” line because of the limitations in immersion length and restrictions to the fluid flow. Surface mount sensors would not provide the required accuracy and would over time be damaged by the ambient conditions. To insure an accurate measurement some type of hybrid surface mount or redesign of the tubing system would be required. The high service temperature further limited the options

Solution

Two solutions were developed using existing designs by extending their capabilities to include 1/4” tube sizes and increasing the temperature limit up to 932°F. First is the Burns Model SNI (sanitary non-intrusive) which required a different mounting technique for the internal sensing element and a different insulating method to handle the high temperature. This sensor can be installed with tube fittings or welded in place. Second option is a modification to the Burns SWE elbow thermowell. By making the internal thermowell 3/16” O.D. and fitting it with a 1/8” diameter RTD the overall package appears as a shrunken version of the 1/2” tube size. An immersion length of 3” or more will insure an accurate measurement.