Your Temperature Measurement Experts

Technical Papers

SWE Time Response Comparison - 0.236” (6mm) vs. 0.25” Sheath - Part 1

Date: 3/5/18

Test Report Number: 18002

Author: Josh Zahorik

Report Subject:

SWE Time Response Comparison – 0.236” vs. 0.25” sheath

Introduction:

A customer has requested information about the performance of a 6 mm sensor compared to a 1/4” sensor when used with an SWE thermowell. This testing will evaluate how varying the sheath size impacts accuracy and time response.

Test Units:

Two 300L style units were built for testing. One sensor had a 0.25” sheath with a 0.020” wall thickness, and the other had a 0.236” (6 mm) sheath with a 0.020” wall thickness. No other changes were made from the standard build. The sensors were tested along with a 3/4” SWE thermowell.

Results:

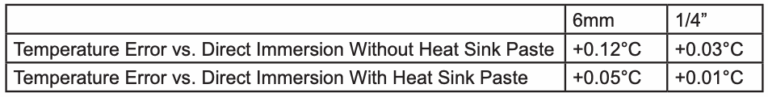

To test accuracy, the thermowell was immersed in an ice bath as shown in Figure 1. Sensors were connected to the thermowell, and the results given in Table 1 were taken once the measurement stabilized. Ambient temperature was approximately 20°C. Changing the delta between the process and ambient temperatures would be expected to change the errors shown proportionately. This test method simulates a well insulated process line, however installations with non-ideal process insulation may see larger variations, and insulating the sensor may help reduce variations shown.

Figure 1: Thermowell immersed in an ice bath

Table 1: Results form Accuracy Testing

To test direct immersion time response, the sensors were immersed in an ice bath, allowed to stabilize, then immersed into water flowing at 3 ft/s and allowed to stabilize. To test time response within the thermowell, the sensors were connected to the thermowell, allowed to stabilize at room temperature, and then ice water was pumped through the thermowell until the measurement stabilized. This process was then repeated with heat sink paste applied to the thermowell bore until it flowed out of the bore. The heat sink paste was reapplied each time the sensor was changed.

Conclusion:

There was a significant performance improvement to both accuracy and time response by using heat sink paste in the thermowell bore. Whether or not heat sink paste was applied, there was also a significant performance improvement when using a 1/4” sensor instead of using a 6 mm sensor with the SWE thermowell.