Your Temperature Measurement Experts

Mini Case Studies from the Field

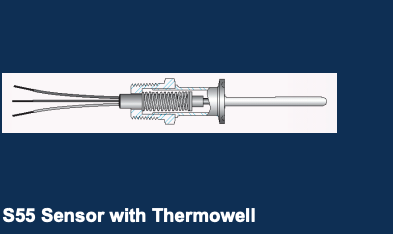

Sanitary Sensor with Integral Thermowell

Application

A pharmaceutical company is using traditional direct immersion sanitary temperature sensors to measure the line temperature in their steam in place process equipment. Validation procedures require the temperature to meet or exceed the minimum sanitization temperature when cleaning the system. To ensure this temperature is met, a regular calibration schedule is set up to ensure each temperature point is accurately measured.

A pharmaceutical company is using traditional direct immersion sanitary temperature sensors to measure the line temperature in their steam in place process equipment. Validation procedures require the temperature to meet or exceed the minimum sanitization temperature when cleaning the system. To ensure this temperature is met, a regular calibration schedule is set up to ensure each temperature point is accurately measured.

Challenge

In order to calibrate the sensors, they must be removed from the process line which means that process must be shut down. The company would like to calibrate the sensors without having to remove them from the process line, but adding a thermowell reduces the time response performance of a direct immersion probe.

Solution

The Series S Sensor with Integral Thermowell is a high performance thermowell assembly for sanitary applications requiring fast time response. The thermowell has a 0.188 inch diameter shank and contains a 0.125 inch diameter spring loaded element. This element can be easily removed for calibration without breaking the process. Its small diameter minimizes time response and can fit in short immersion applications found in small diameter process lines