Your Temperature Measurement Experts

Mini Case Studies from the Field

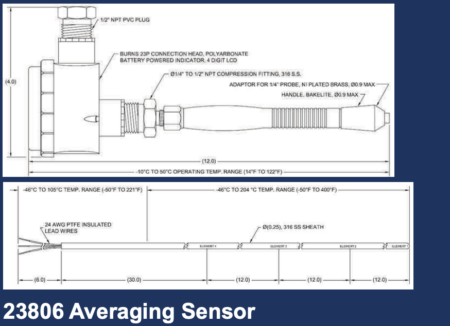

Measuring Averaging Temperature for Better Beer Brewing

Application

Application

A local brewing company wanted to have better temperature control over their mash tun. This tank is where the milled grains are mixed with water to form the “mash”. Varying the temperature will activate different enzymes and affect which sugars are produced. Having an accurate temperature measurement for the mash tun is vital to creating the right flavor and feel of the beer.

Challenge

The harsh environment inside a steam autoclave of alternating vacuum and steam, causes standard RTDs to fail quickly. The vacuum pulls the air out of the probe and when the vacuum is removed the steam rushes in and causes low insulation resistance and a corresponding low temperature reading. A pressure and water tight seal is an absolute necessity on the probe and also where the lead wires exit the autoclave. Durability is also very important especially in the larger autoclaves where carts full of equipment to be sterilized are wheeled in and out frequently. The temperature probes are frequently dropped, run over, or the cable gets caught on things and pulled. Any of these can cause damage to the cable jacket and the moisture and pressure seal for the probe is lost.

Solution

A hand held RTD probe with a battery powered indicator was designed to accurately measure the average temperature of the full depth of the mash tun. With four evenly spaced sensing elements, the RTD averaging probe is sensitive to temperature change along the full length of the sensor. The waterproof head mounted indicator is battery powered which allows the user to get a reading without the use of a control system or having to install wires for power.