Your Temperature Measurement Experts

Mini Case Studies from the Field

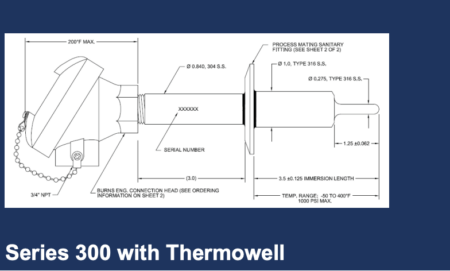

High-Vibration Sanitary Solution

Application

A food processor was having difficulty measuring temperature with an RTD in a location that had a high degree of vibration. Standard sensors would fail quickly. A switch to a more durable thermocouple was considered but it did not provide the required accuracy for the measurement point. In addition to vibration there was a steam injector upstream from the sensor which caused a mechanical shock to the sensor when activated.

Challenge

Line size, need for a sanitary connection, flow obstruction, process temperature, and 3A sanitary requirements were some of the constraints that had to be considered for designing an effective solution. There was no possibility of relocating the measurement point or reconfiguring the tubing layout.

Solution

When approaching a vibration/shock problem there are three main ways to solve it. Eliminate the source, isolate the sensor from the vibration, or beef up the sensor. In this case the decision was to beef up the sensor. Heavy wall, large diameter tubing was used along with the Burns Series 300 style heavy duty sensing element package. This combination stiffened up the sensor minimizing vibration enough so that the sensing element now provides years of high accuracy service.