Your Temperature Measurement Experts

Mini Case Studies from the Field

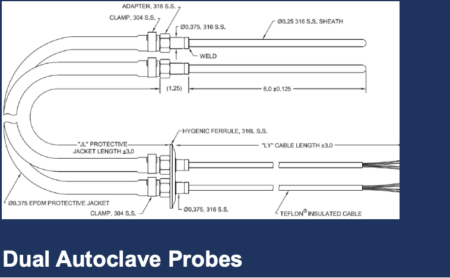

Dual Probe Autoclave Sensor

Application

Application

Steam autoclaves are used to sterilize a variety of equipment and present a difficult environment for an RTD (resistance temperature detector) the sensor of choice for most autoclaves. In addition to the temperature control sensor there are other sensors that monitor the temperature of items being sterilized and the temperature within the autoclave. Each is exposed to a high vacuum and then a steam environment at 121°C and need to maintain a high accuracy repeatable measurement. Access for installing the monitoring sensors is typically through a hygienic ferrule which has to have a vacuum tight seal.

Challenge

Standard industrial RTDs are not designed to withstand the vacuum and steam environment in an autoclave. Their moisture seals will fail quickly resulting in a low temperature reading. Installation in an autoclave involves two big challenges, one is that the sensor needs to be sealed from moisture and pressure changes, and it also needs to be very durable. Sometimes during the loading and unloading of items to be sterilized, the sensors get dropped, tugged on by the cable or other handling mishaps. The second challenge is that the number of entries into the autoclave is limited which poses a problem if more than one sensor is required.

Solution

Burns Engineering manufactures a line of RTDs for autoclaves that have the durability and moisture resistance to withstand the environment in a steam autoclave. The Model SAH heavy duty autoclave RTD was modified for this application to allow for two sensors to be installed through a single 2” hygienic ferrule. The Model SAX has this feature but it is designed for walk-in size autoclaves whereas the SAH is designed for smaller units where increased flexibility of the lead wires is needed. An EPDM hose covers the lead wire from each sensor providing excellent durability, strength, and moisture protection for the RTD