Your Temperature Measurement Experts

Mini Case Studies from the Field

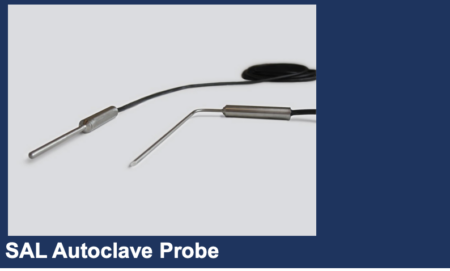

Autoclave Temperature Probe

Application

Need to monitor the temperature inside of a steam filled vacuum chamber. Pharmaceutical manufacturers experience frequent failures of temperature sensors used in steam cleaning autoclaves. Problems are caused by any break in the seal of the sensor or its attached lead wire. The failures occur when the process is completed and left over moisture condenses. When the vacuum is removed, capillary action can allow the condensed moisture to reach the sensing element, necessitating replacement of the probe.

Need to monitor the temperature inside of a steam filled vacuum chamber. Pharmaceutical manufacturers experience frequent failures of temperature sensors used in steam cleaning autoclaves. Problems are caused by any break in the seal of the sensor or its attached lead wire. The failures occur when the process is completed and left over moisture condenses. When the vacuum is removed, capillary action can allow the condensed moisture to reach the sensing element, necessitating replacement of the probe.

Challenge

Sensing element must be completely sealed from moisture. To prevent frequent failures and replacement of sensors it is imperative that the sensing element is not exposed to any moisture. The two key areas of concern are the transition fitting on the probe, from stainless steel probe to lead wire, and the lead wire cable itself. The transition fitting must have a seal that can withstand the vacuum pressure and is impervious to moisture. Cable must be able to be sealed easily through the wall of the autoclave.

Solution

Design a moisture proof sensor that can withstand rough environments. Burns engineers designed the autoclave probe with a moisture and pressure proof fitting. This fitting seals the transition from stainless steel probe to silicone rubber insulated cable. The cable is a heavy-duty design that can withstand repetitive movement and is resistant to cutting and abrasion. Burns autoclave probe is capable of providing accurate temperature sensing through numerous autoclave cycles. In addition to the standard ¼ inch design, Burns offers tube diameters of 3/16” and 1/8”. A 90 degree bend and a sharpened tip are popular options for load cells. All are available with dual 4 wire sensing elements.