Your Temperature Measurement Experts

Mini Case Studies from the Field

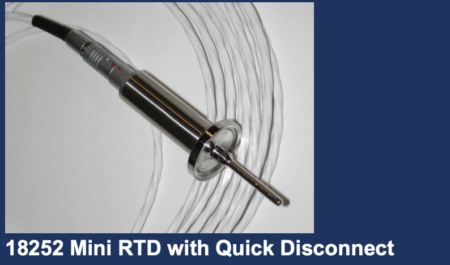

Quick Disconnect Saves Time

Application

Application

Mini sanitary temperature sensors manufactured for measuring and controlling the temperature in batch process vessels for the pharmaceutical industry.

Many sanitary applications involving batch processing require that the vessel is cleaned between each run. Normally the vessel is rolled to a different area where it is sanitized. To accomplish this, all external attachments must be disconnected and removed from the vessel.

This pharmaceutical company has determined that the time associated with disconnecting the vessel was effecting the production capability and plant performance. They wanted to increase their efficiency and maintain the same high level of sanitization.

Challenge

Offer a new sensor design that would reduce the time to disconnect the lead wires/ RTD from the vessel.

The mini sanitary sensors used for this application are commonly supplied with up to 50 feet of lead wire so that the signal can be sent directly back to the DCS or PLC. The lead wire is normally run back through a wire tray. Each time the sensor is replaced or removed, a technician must pull the wire out of the tray.

The vessel is then wheeled to an area where is either run through an autoclave or cycled through a wash down to meet plant sanitization requirements.

Solution

A Mini sanitary sensor with a quick disconnect cable.

The mini sanitary sensor incorporates a quick disconnect that requires no special tools to undo. The probe is designed for both wash-down applications and may also be sterilized in an autoclave.

By designing the quick disconnect cable, the customer was able to reduce their maintenance costs, improve their efficiency and maintain the same level of sanitization.