Your Temperature Measurement Experts

Mini Case Studies from the Field

Temperature Measurement in an Ultrasonic Bath

Application

Application

Ultrasonic vibrations are interfering with the temperature measurements in the bath. A biotechnology company uses ultrasonic baths to clean their machined parts to sanitary standards. This process requires precise control of the temperature of their ultra-sonic bath. When the ultrasonics are on, the bath tempera-ture measures 9 degrees higher that actual. When the ultra-sonics are off, the bath temperature reads normal. To cor-rect this, they have manually adjusted the set point to cor-rect for the 9 degree error. However, they cannot maintain control over the bath temperature in both modes of opera-tion.

Challange

High frequency vibrations causing resistance shift in sensing element. Together we ruled out noise and interference effects in both the sensor and instrument. We determined that the sensor element must not be supported properly in its package and must be vibrating to give the error in reading.

Solution

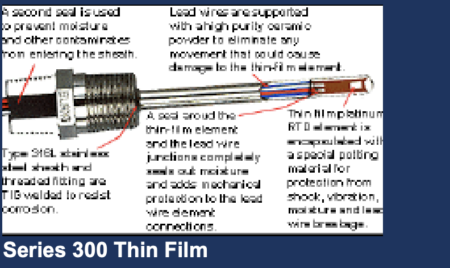

Series 300 thin film RTD: engineered for resistance to shock and vibration. We replaced the OEM sensor with our Series 300 thin film sensor. The Series 300 sensing element is completely sup-ported and resistant to vibrations. The problem was fixed and the customer no longer needs to adjust their instrumen-tation.