Your Temperature Measurement Experts

Mini Case Studies from the Field

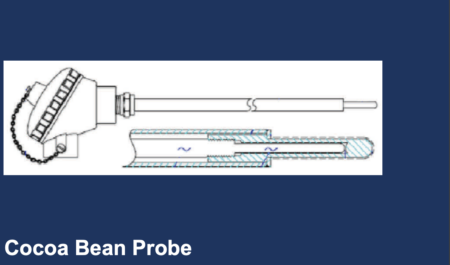

Cocoa Bean Roaster RTD

Application

Application

Abrasive nature of cocoa beans is destroying temperature probes. A chocolate manufacturer needs to monitor the temperature of a cocoa bean roaster. The beans are poured into the rotating roaster and are continuously agitated. In this process the cocoa beans come into direct contact with the RTD probe. The beans shells are very abrasive and wear through the probes sheath on a regular basis.

Challenge

The sensing element of the probe is located at the tip of a 5’ long probe. Previously the sensing element was an integral part of the 5’ probe. When the small tip would wear out, this necessitated replacement of the entire probe. This is both costly and time consuming. It would be advantageous to the user to be able to replace only the worn out tip and retain the rest of the probe.

Solution

Design a modular probe that would replace the existing 5’ probe, but had a removable sensing element and tip. Since the roaster is designed for use with the 5’ long probe, it did not make sense to try to redesign the entire system. Instead Burns’ engineers designed a probe with a removable tip that threads into the end of the 5’ probe. This saves the customer time and money when the tip requires replacement at regular intervals. The customer now has an economical and hassle free solution for sensor tip replacement.